Great ideas deserve great execution.

Our design and production experts are dedicated to delivering elevated

brand experiences that create lasting impressions.

We’re fueled by creativity and driven to execute your brand strategy in

ways that will captivate and inspire.

Baltimore Museum of Art: Dew Drop Inn

Museum Exhibition Graphics

YankeeKicks

In-Store Signage & Product Fixtures

Nike Well Collective

Exterior Wall Graphics

Highland Fleet

EV Charging Station Wraps

Pizza Hut

Event Fabric Graphics

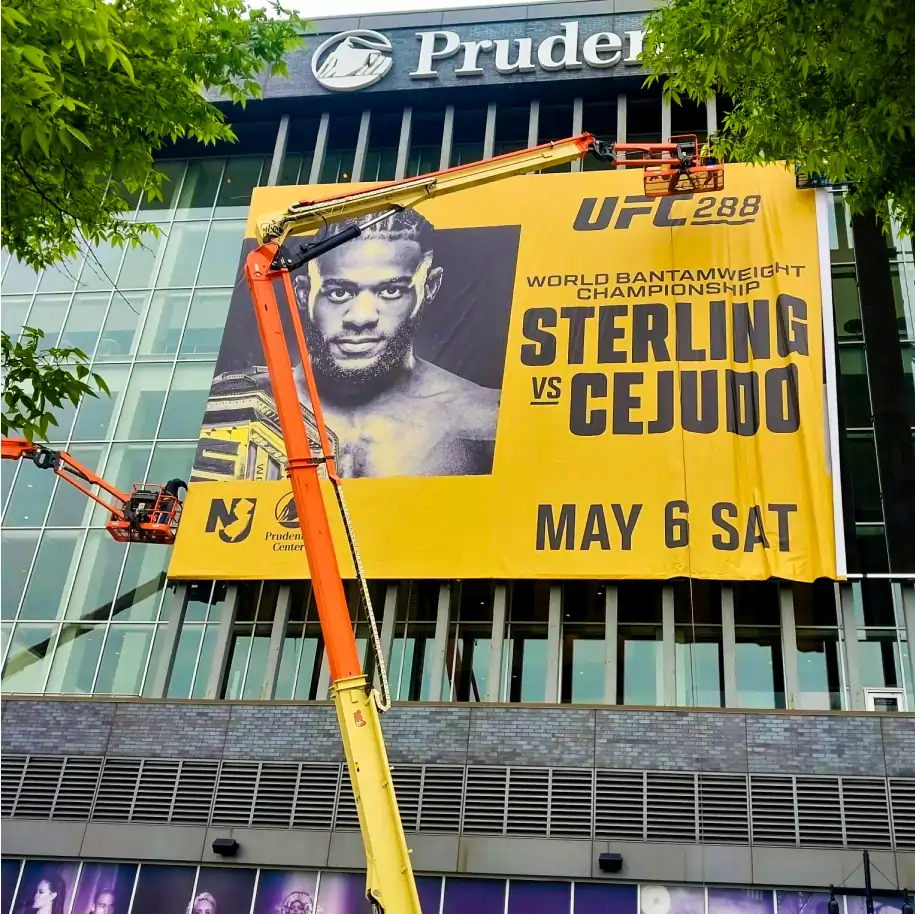

Prudential Center

Large-Format Banner

Crunch Fitness

Large Format Signage

Shake Shack

LED Signs

Wayfinding Restroom Signage

Award-Winning Wayfinding Signage

5G

Custom Displays

Abercrombie & Fitch

Backlit Letters + Logos

Brooks Ghost Max

Product Display

Tribeca Window Graphics

Window Graphics

Summer for the City

Event Graphics

LightenUp SEG

SEG Fabric Backlit Display

BeMatrix

Trade Show Display

Cooper University Health Care

Feature Wall

BJC Home Health

Vehicle Wrap

HCLTech

Large Format Signage

Life Time UltraFit

Recycled Acrylic Room Dividers

Lunds & Byerlys - Model Ts

LED Wall Panels

Lunds & Byerlys

Custom LED Fixture

Lincoln Center Stage

Vinyl Stage Graphics

US Open: Fan Experience

Fan Experience

H&R Block

Window Graphics

Mortenson Trailer

Trailer Wrap

Nike Live Exterior

Building Wrap

Starbucks Reserve 01

Custom Design and Engineering

Starbucks Reserve 02

Custom Fabrication and Prototyping

Starbucks Reserve 03

Custom Countertop Sign

Mortenson

Wall Graphics

Neiman Marcus

Building Wrap

Olaplex Display

In-Store Retail Display

Starbucks Window Display

Storefront Window Display

Adidas

Specialty Sneaker

Store Exhibit

Tatcha

Experiential Retail

Pop-Up

Burberry London

Wide-Format

Floor Graphic

Nike

Wide-Format

Window Display

Bunch Creative

SEG Fabric

Lightbox Display

Eddie Bauer

Storefront

Window Display

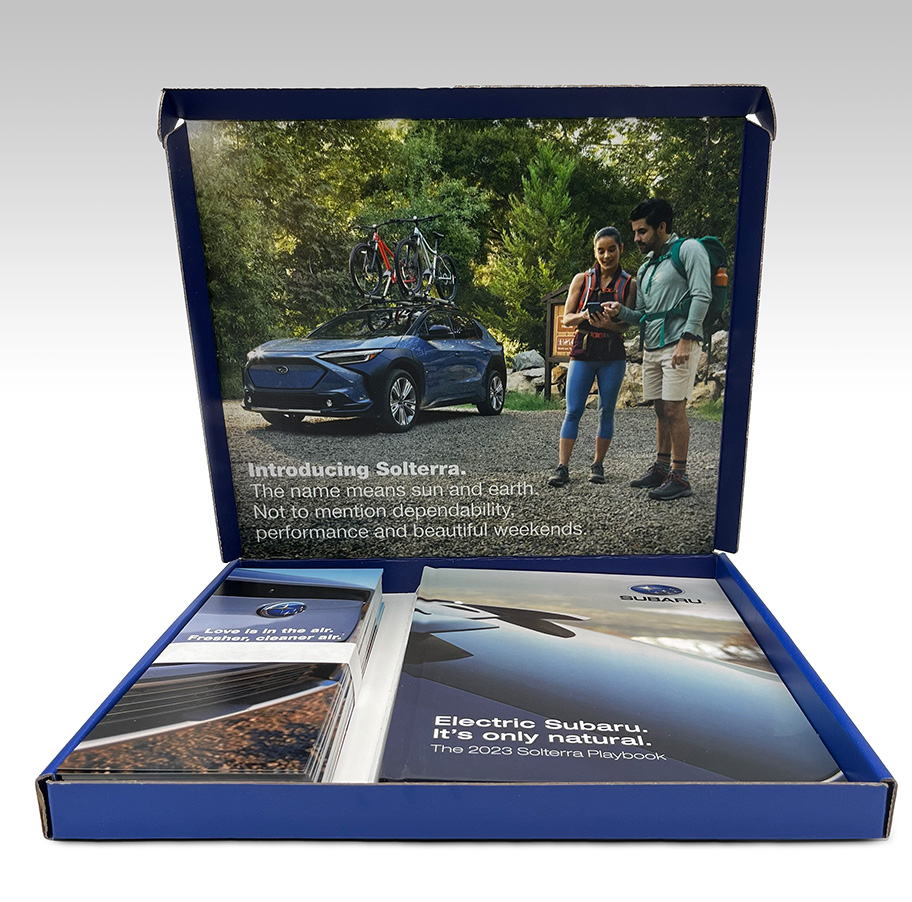

Subaru

Dealership

Mailer Box

Alaska Airlines

Trade Show Booth with

Entertainment/

Presentation Components

Sentry

Neon Sign on

Vinyl Wall Mural

Athleta

Retail Wall Mural

Starbucks

Modular Roastery

Merchandise Table

Dior

Grand-Format

Window Installation

Jack Daniel's

Basketball Court

Floor Graphic

Giselle Burberry

Building Billboard Wrap

MNUFC

Professional Soccer

Wall Mural

Lockheed Martin

Trade Show Booth

with Presentation Stations

and Private Meeting Rooms

Columbia

Freestanding Acrylic

Window Display

Macy's

Grand-Format

Storefront Installation

Gilaman Brothers

Oversized Infinity Board Exhibit

Peacock

Interactive Chair Stand

Carefield

Vehicle Wrap

Sephora

Universal Chrome/

Infinity Board

Merchandiser

Brooks

Freestanding

Shoe Display

Republic Wireless

Retail Shelf Display

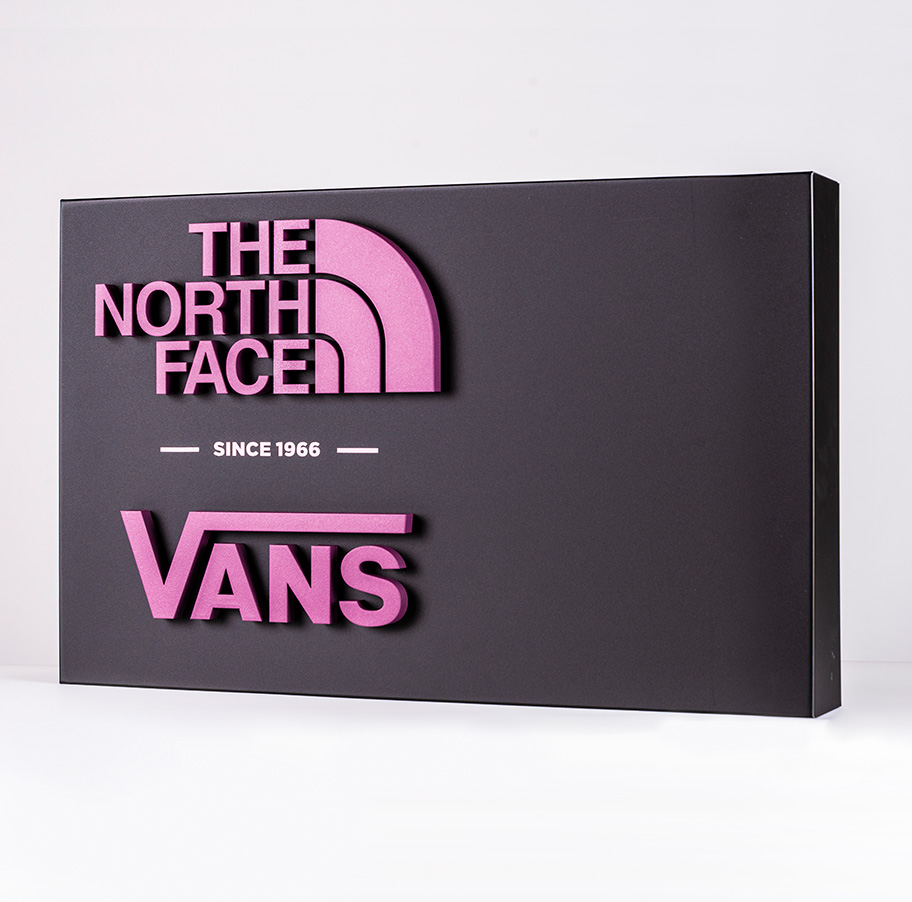

The North Face

Footwear Display

Minnesota Timberwolves

Professional Basketball

Wall Logo

Morris

Backlit Custom Island

with Aerial Signage

Target Center

Professional Sports

Arena Cover

VSP

Bike Locker Wrap

Charlotte's Web

Modular Retail Display

Ducati

Decal and Collateral Kit

Landry's

Corrugated Shipper Display

Golf Pride

Freestanding Merchandiser

Learn how Taylor can bring your vision to life.